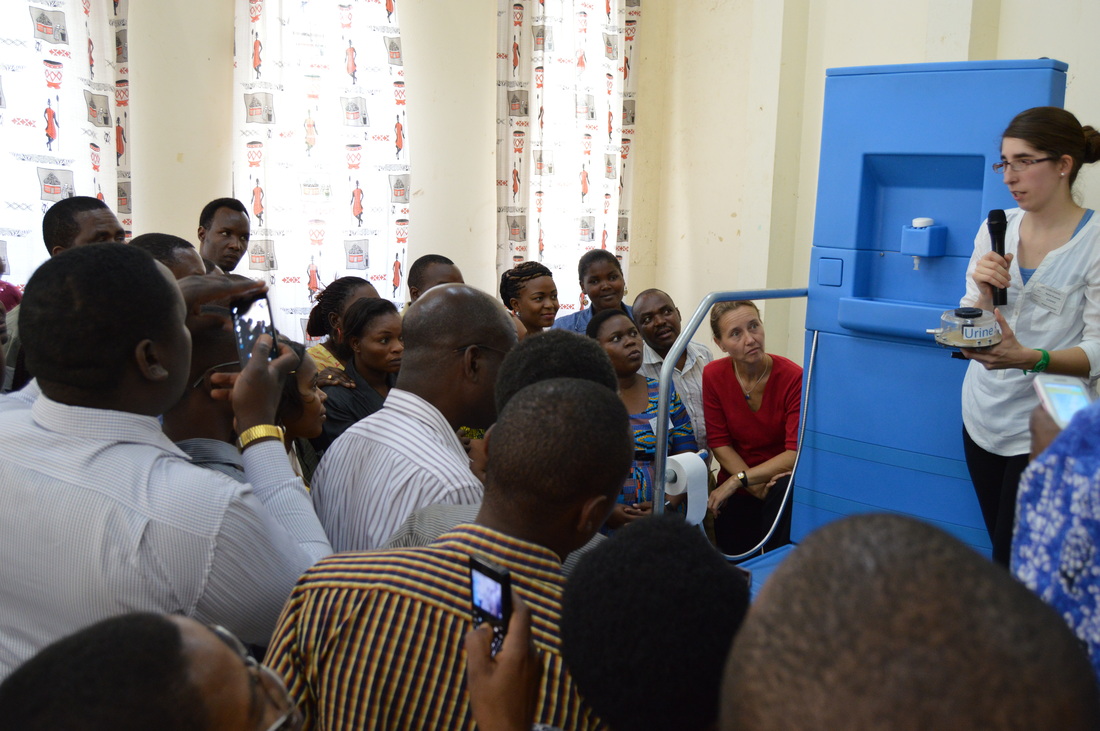

In Moshi, Tanzania, the public authorities Kilimanjaro Regional Secretariat (RS), Moshi Municipal Council (MMC) and Moshi Urban Water & Sanitation Authority (MUWSA) with the support of GIZ invited around 80 local stakeholders from the 28 to 29 of January 2015 for the workshop Sanitation in Moshi, where Rahel Künzle, our Blue Diversion Engineer presented the toilet to the public.

The workshop agenda included critical discussions about national sanitation approaches and programs, the illustration of Moshi’s sanitation situation reflected in the famous ‘Shit Flow Diagram’ and the presentation of new technical sanitation solutions. The participants considered the blue toilet as a highlight that clearly shows a modern sanitation solution with the additional benefit of opening business options by selling urine as fertilizer. Such options can be valuable for towns like Moshi where estimates show that over 80% of waste water and fecal sludge ends up untreated in the environment: being dumped in gutters, streams or percolates into the ground water. At the end of the workshop the Regional Secretariat Moshi and the Municipality signed a Memorandum of Understanding to formalize and intensify collaboration on hygiene and sanitation issues in the municipality of Moshi.

Read more on "Support to the Water Sector Development in Tanzania"

by Stefanie Enssle

The workshop agenda included critical discussions about national sanitation approaches and programs, the illustration of Moshi’s sanitation situation reflected in the famous ‘Shit Flow Diagram’ and the presentation of new technical sanitation solutions. The participants considered the blue toilet as a highlight that clearly shows a modern sanitation solution with the additional benefit of opening business options by selling urine as fertilizer. Such options can be valuable for towns like Moshi where estimates show that over 80% of waste water and fecal sludge ends up untreated in the environment: being dumped in gutters, streams or percolates into the ground water. At the end of the workshop the Regional Secretariat Moshi and the Municipality signed a Memorandum of Understanding to formalize and intensify collaboration on hygiene and sanitation issues in the municipality of Moshi.

Read more on "Support to the Water Sector Development in Tanzania"

by Stefanie Enssle

RSS Feed

RSS Feed